Currently, various tools are used in auditing activities that enable and support the auditing process, including:

- check-lists;

- control lists;

- questionnaires;

- 8D method;

- 5 Why method;

- Ishikawa diagram – cause and effect diagram;

- audit trail.

The use of these tools ensures the implementation of one of the principles, including QMS in accordance with the international standard ISO 9001 – making decisions based on evidence. They allow for obtaining evidence and reliable information about the condition of the examined objects. The choice of a tool and how it is used depend on the purpose and a number of circumstances.

Human memory is unfortunately imperfect, so even professionals sometimes make mistakes that can become catastrophic problems. Therefore, various types of audit documents are used, including checklists, controllists, notes etc.

| No. | Point ISO 9001 | Question | Yes | No | Comments

|

| 1 | 4.1 | Understanding the essence of the organization and its context | □ | □ | |

| 2 | 4.2 | Understanding the needs and expectations of interested parties | □ | □ | |

| 3 | 4.3 | Determining the scope of operation of the quality management system | □ | □ | |

| … | …. | … | □ | □ | … |

| m | 8.5.1 | Supervision of production and service delivery | □ | □ | |

| n | 8.5.2 | Identification and traceability | □ | □ |

|

Table 1 An example of a check-list

The most common auditor working documents are checklists or controllists. The check-list usually includes a number of necessary controls, e.g. for a process or any checked activity / work (Table 1). By checking items on the list, the auditor can find out about the status / correctness of activities. We transform opinions and assumptions into evidence from a check-list. The completed controllist is objective evidence that an audit has been carried out (Table 2).

| Business: | Department: | Report no | |||||

| Position | Point ISO 9001 | Issue | Auditor’s remarks | Time | |||

| 1 | 5.2 | Check the availability and knowledge of the Quality Policy by employees. Ask employees how they understand the policy. | 15 min | ||||

| 2 | 7.2 | Staff competences, check supporting documents. | 10 min | ||||

| 3 | 8.7 | Check for complaints, including the marking of the complaint area in the warehouse. | 10 min | ||||

| … | … | Other matters | |||||

| Auditor: ……………………. | Date: ……………………….. | Signature: ……………………… | |||||

Table 2 Sample controllist

Questionnaire – is an SMS document with a set of structured questions in paper or electronic form created in order to obtain an answer.

The questionnaires use open questions – any formulation of the answer, closed – the respondent selects answer variants and semi-open questions – closed questions with one open question in the answer variants. A questionnaire is used – the respondent answers himself and the interview questionnaire – the auditor asks the respondent questions and writes down the answers. Below is an example of a self-assessment questionnaire – used in the QMS (Table 3).

| SELF-ASSESSMENT QUESTIONNAIRE | ||||||

| Name and number audit tasks: Document No. rob. Performed by: Approved by: | No: 19 / 20__

Date: __.__. 20XX. Date:

| |||||

| Please provide your answer as an attachment | Yes | No | If not, please specify the deadlines | Responsible person signature | Comments | |

| Has a Steering Committee been established? | ||||||

| Has a Project Manager been appointed? | ||||||

| Has the project management method been adopted? | ||||||

| … | ||||||

Table 3 An example of a self-assessment questionnaire

8D method – it is used to solve problems and deviations in processes related to e.g. production, quality, purchasing, design, occupational health and safety, customer service, warehousing. It consists of actions in the following order: creating a working group of auditors and specialists, describing the problem, introducing corrective action, finding the root cause, taking corrective action and verifying it, implementing preventive action and evaluating, issuing a report. The auditor uses this method during the audit to verify the cause of non-compliance. For example, in the case of a product complaint by a customer, top management may commission the auditor or the audit team to conduct an audit and verify the occurrence of nonconformity / observation, indirect and root cause.

5Why Method – is a problem-solving method consisting of a series of questions that allow you to find the root cause of the problem. During an audit, the method is applicable when detailed problem identification is needed to adequately indicate the classification of observations and to present evidence objectively.

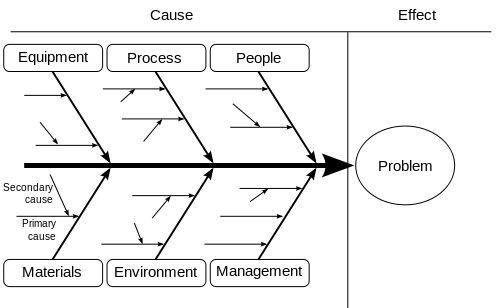

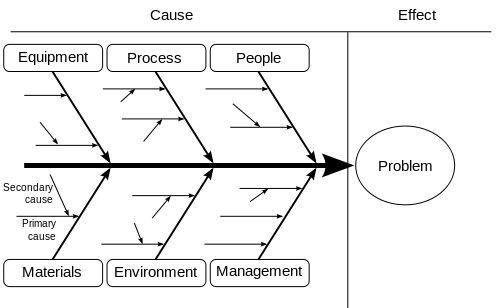

Ishikawa diagram – the method consists in determining the problem, and secondly, identifying and determining all the causes that caused the identified problem. The causes are classified into categories presented in Figure 1. The auditor, looking for key evidence, has the opportunity to carefully check each of the categories. By asking additional questions, the auditees are able to effectively identify the main cause of non-compliance.

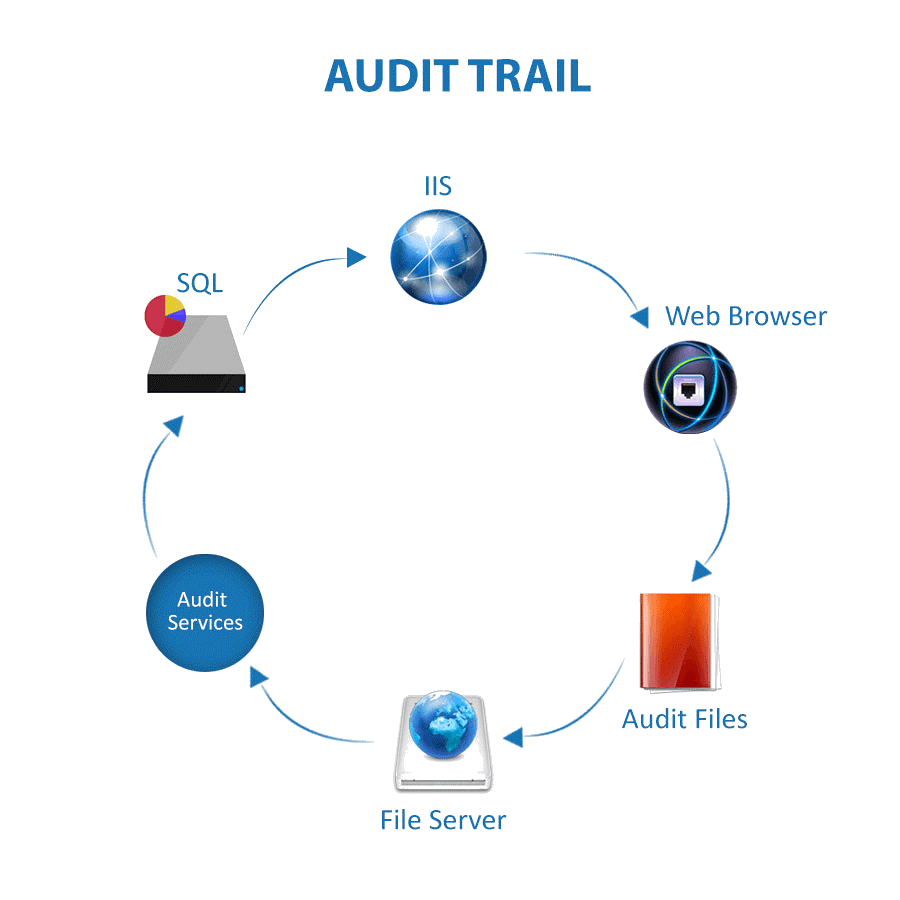

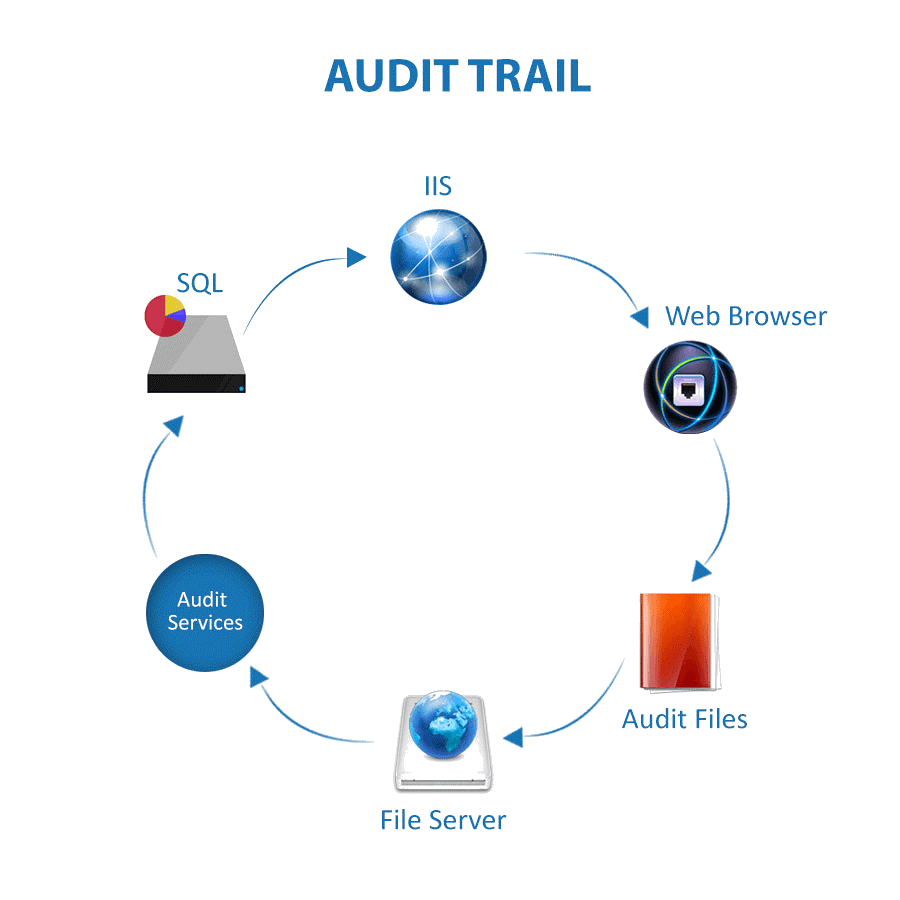

Audit trail – a complex document, contains a clear description of the operation and process from the beginning, during their duration, until the end. Describes how to document and control operations or processes. It is a tool that supports the process of internal control and auditing of quality management systems, it enables the detection of errors and inconsistencies in the process.

The path includes the following information about the audited process, which are:

- activities and tasks performed as part of the audited process;

- time frame of the process or operation;

- relationship between the auditee and the process;

- the possibility of eliminating or simplifying the process.

The path must specify: activity, subject, estimated time of completion, manner and place. An example of a path is the documentation flow process in the company defined by a standard procedure. The diagram of the audit trail is shown in Figure 2, it is a document flow of the company, in which electronic documentation is used.

A modern solution in the case of auditing management systems is the use of the CAQ (Computer Aided Quality) IT tool – computer aided quality control. The software supports the processes related to quality management and is used for: analysis of processes in the enterprise, supervision of documentation and records from controls and audits, risk assessment in the organization, supervision of threats and non-conformities.

The software from the CAQ family significantly improves processes, plans activities taking into account time savings, gathers information about the system in a database, and enables users to work remotely.

The introduction of such a solution is associated with costs and requires the appropriate preparation of the IT infrastructure of the organization.

We propose to use tools verified by our auditors, which combine elements of a checklist and a questionnaire, details on ikmj.org –https://ikmj.org/kategoria-produktu/audyt/

Sources used:

PN-EN ISO 9001: 2015-10: Quality management systems – requirements, Polish version, PKN

PN-EN ISO 19011: 2018-08: Guidelines for auditing management systems, Polish version, PKN

Robert Karaszewski – Modern Concepts of Quality Management, Publishing House of the Scientific Society of Organization and Management House of the Organizer, Toruń 2009